Ceramic materials have excellent properties such as high temperature resistance, low density, high specific strength, high specific modulus, oxidation resistance and ablative resistance, etc., which make them have the potential to replace metal as a new generation of high temperature structural materials.

Baed on Al2O3 fiber, ceramic matrix composites can be used in supersonic jet nozzles and gaskets in rocket engines etc.

There are many properties of ceramics that make them desirable for aerospace applications. The most important are lightweight, high temperature resistance, electrical insulation, high energy of ablation, resistance to corrosion, chemical stability, wear resistance, and ability to withstand vibration.

Advanced ceramics underpin the electronics industry, and the average aircraft is packed full of electronics. Gradually, these electrical components, such as sensors, antennas, capacitors and resistors, are getting increasingly smaller and more capable. Therefore, this is a major area of development for advanced ceramics.

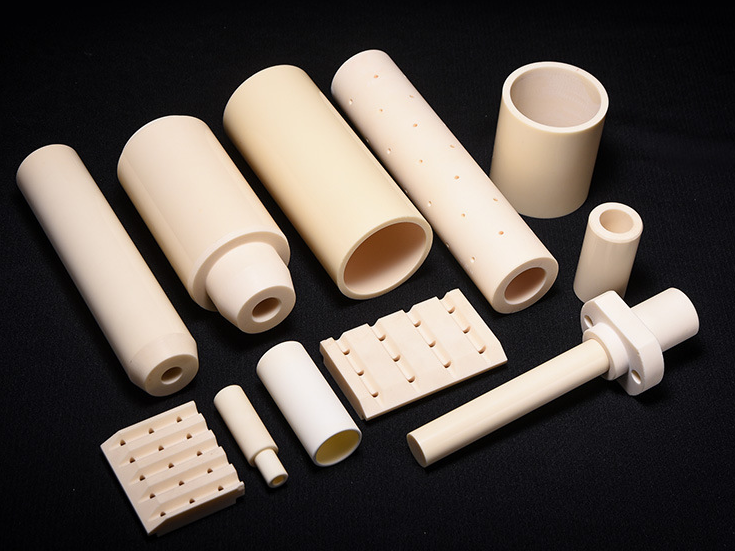

Structural ceramics (crystalline inorganic non-metals) are used in aerospace as thermal barrier coatings (TBCs) in the hot part of the engine. In addition, these materials are being used in composites either as reinforcement and/or as a matrix such as in ceramic matrix composites (CMCs). Being lightweight and tough tends to be a main driver for using a ceramic composite.

Ceramics are lighter than most metals and stable at temperatures substantially above high-grade technical plastics. As a result of these and other properties, structural ceramic applications include thermal protection systems in rocket exhaust cones, insulating tiles for the space shuttle, missile nose cones, and engine components.

Technical ceramics have been used for various parts of the engine for the past 30-40 years, but a lot of activity currently surrounds the development of silicon carbide (SiC/SiC composites) for use in jet engine turbines, mainly concentrated on the turbine blades. The main driver is fuel efficiency, as engineers seek to run the jet engine without the need for cooling channels that currently stop the metal alloy blades from melting. If the blades were made of ceramic composites, which could deal with temperatures of 1,500-1,600°C, the engine could run at higher temperatures. Energy efficiency would therefore increase, which leads to less fuel and the airplane’s ability to fly further or more efficiently.